Plastic Packaging Industry 2025: Why PE Film Remains the Smart Choice for Manufacturing & Logistics

In a fast-changing market where input costs are rising and packaging requirements are becoming more demanding, PE film (Polyethylene film) continues to hold its ground as one of the most essential materials in the packaging industry—thanks to its flexibility, durability, and cost efficiency.

Global Plastic Packaging Demand Continues to Surge

According to industry projections, global plastic packaging demand is expected to exceed 103 million tons in 2024 and grow to nearly 123 million tons by 2029. With a compound annual growth rate (CAGR) of 3.56%, the data reflects increasing packaging needs across manufacturing, e-commerce, logistics, and agriculture.

.png)

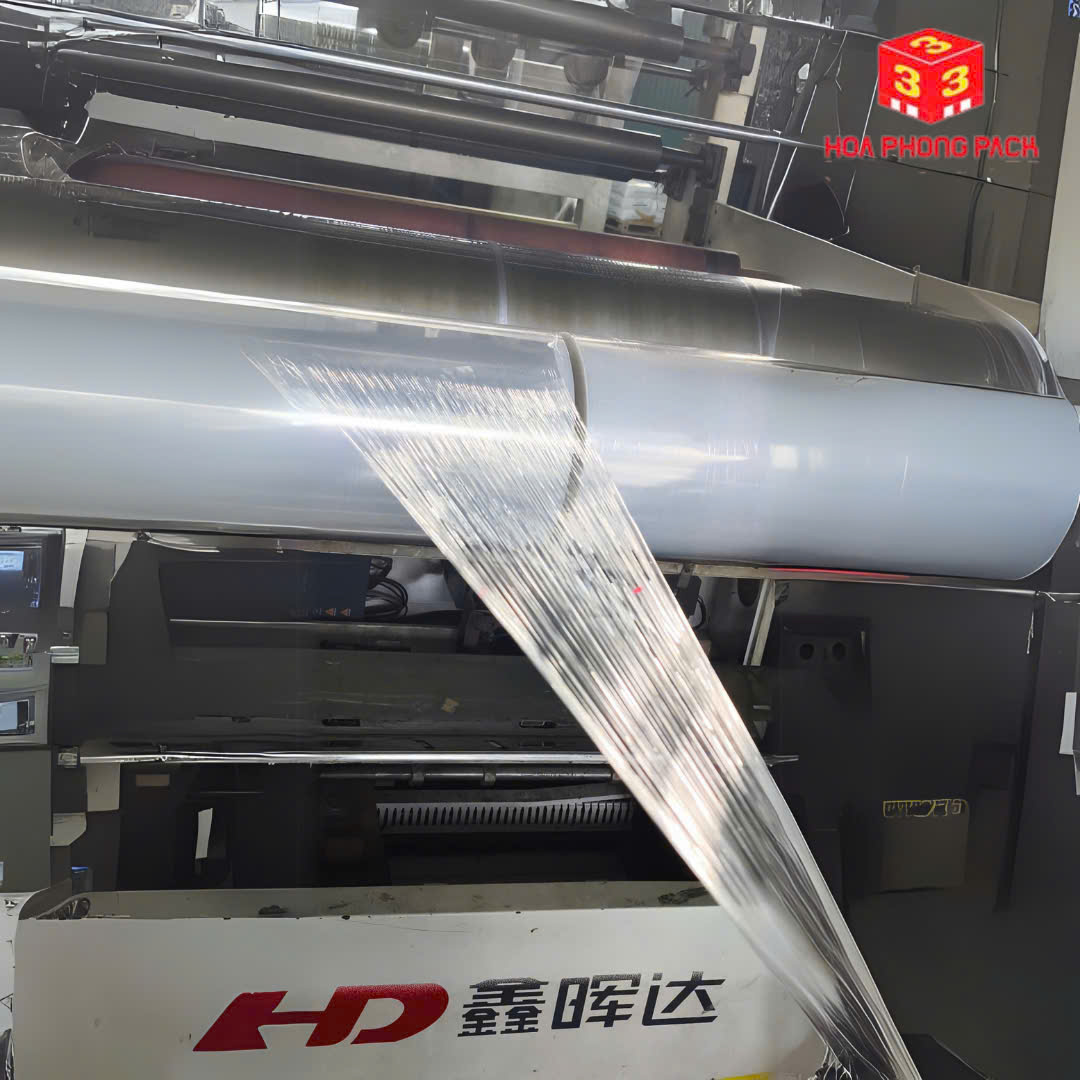

Why PE Film is Indispensable in Modern Packaging

PE film, produced from LDPE (Low-Density Polyethylene), offers high flexibility, strong stretchability, and reliable cling—making it ideal for:

-

Wrapping pallets and securing goods during transit

-

Shielding products from dust, moisture, and scratches

-

Use in industrial packaging, warehousing, spas, agriculture, and construction

Its ability to conform to different shapes and protect products under various conditions makes PE film a versatile and economical packaging solution for businesses of all sizes.

Finding Opportunities in Market Shifts

In Vietnam, the proposed import tax hike on LDPE has raised concerns among plastic manufacturers. However, this evolving landscape also opens up opportunities for smart businesses to:

-

Secure stable, cost-effective raw material sources

-

Streamline operations to reduce production waste

-

Focus on product quality to maintain competitive edge

High-quality PE film reduces packaging risks and minimizes product loss—making it a preferred material for producers, logistics companies, and warehouses seeking consistent performance.

Staying Connected to Industry Trends

Events such as the “Young Packaging Awards 2025” and regular packaging forums hosted by Vinpas (Vietnam Packaging Association) are creating a dynamic knowledge-sharing environment. These platforms help Vietnamese businesses stay ahead of trends, adopt new technologies, and build more resilient production strategies.

Conclusion

In today’s competitive market, businesses don’t just need attractive packaging—they need packaging materials that perform, last, and reduce operational costs. While not biodegradable, PE film remains a smart choice due to its proven efficiency, affordability, and adaptability in real-world applications.